When to Look Beyond Silicone Sealant

Silicone is a reliable sealant, but specific project demands often require a different solution. Recent market volatility also drives this shift. A major supply chain disruption in 2021 caused silicone prices to increase by 300% in under two months, forcing many professionals to explore more stable and high-performing alternatives. Factors like power rationing in China, which produces most of the world’s silicon metal, and global logistical delays created a perfect storm. This environment highlighted the need for versatile sealants that solve problems beyond just availability.

Your Project Requires Painting

One of the most common reasons to choose an alternative is the need for a paintable surface. Standard silicone sealants are silicone-based, meaning they repel water and, unfortunately, paint. Paint will not adhere properly to a cured silicone bead, leading to flaking, peeling, and an unprofessional finish.

Pro Tip: For a seamless, color-matched seal on trim, siding, or walls, a paintable sealant is non-negotiable. Hybrid polymers and some polyurethanes are specifically formulated to be overpainted after curing.

You Need Superior Strength and Durability

Construction and industrial applications often demand more than a simple waterproof barrier. They require a sealant that contributes to the structural integrity of a joint. Alternatives like polyurethane excel in these scenarios, offering significantly higher tensile strength and abrasion resistance compared to silicone. This makes them ideal for high-traffic areas, expansion joints, and applications where superior weathering performance is critical. While polyurethane offers immense strength, some users note health concerns related to its isocyanate content during application, making proper handling essential.

You Are Sealing Dissimilar Materials

Projects frequently involve joining two different types of materials, such as vinyl window frames to a concrete wall or wood trim to metal siding. These materials expand and contract at different rates with temperature changes. Many polyurethane and hybrid polymer sealants offer superior adhesion and greater joint movement capability. This flexibility allows them to maintain a durable, waterproof bond between dissimilar substrates without cracking or pulling away, ensuring a long-lasting and reliable seal.

You Need Better UV or Chemical Resistance

Standard silicone sealants perform well in many situations, but they have vulnerabilities. Prolonged exposure to direct sunlight and harsh chemicals can cause them to degrade. Ultraviolet (UV) radiation from the sun breaks down the polymer structure in some silicones. This process leads to yellowing, chalking, and eventual cracking, which compromises the waterproof seal. For projects facing constant sun or chemical contact, a more robust solution is necessary.

Hybrid polymers and polyurethane sealants offer superior resilience in these demanding environments. They are specifically engineered to withstand environmental stressors that cause other sealants to fail.

·UV Resistance: Hybrid (MS Polymer) sealants are an excellent choice for exterior applications. They contain UV stabilizers that prevent discoloration and degradation from sunlight. This makes them ideal for sealing around windows, doors, and on siding exposed to intense sun, ensuring the seal remains flexible and intact for years.

·Chemical Resistance: Polyurethane sealants provide exceptional durability against chemical spills. They resist damage from fuels, oils, solvents, and harsh cleaning agents. This makes them the preferred option for sealing joints in commercial kitchens, automotive garages, factory floors, and other industrial settings where chemical contact is frequent.

·Choosing a sealant with the right resistance profile is a long-term investment. It prevents premature failure, reduces maintenance costs, and ensures the integrity of the structure over time. A sealant that fails early requires costly removal and reapplication, making the initial material choice critical for project success.

Understanding Polyurethane (PU) Sealants

Polyurethane (PU) sealants are powerful, moisture-curing adhesives known for their toughness and strong bonding capabilities. Professionals often choose them for demanding construction and industrial jobs where mechanical performance is paramount. Their unique chemical structure provides a durable yet flexible seal that withstands significant stress.

Key Benefits of Polyurethane

Polyurethane sealants offer a unique combination of strength and elasticity. Their polymer chain contains both hard and soft segments. This design creates a product that is both highly durable and flexible, making it a top choice for challenging sealing tasks. Key advantages include:

·Exceptional Adhesion: PU sealants exhibit powerful adhesion to most construction materials. They bond especially well to porous substrates like concrete, masonry, and wood.

·High Elasticity: These sealants accommodate significant joint movement from temperature changes, wind, or vibrations. This flexibility prevents the seal from cracking or failing over time.

This combination ensures a long-lasting, watertight seal even in dynamic environments.

Limitations and Handling

While powerful, polyurethane sealants have specific handling requirements. They contain isocyanates, which can be irritants before the sealant fully cures. Proper personal protective equipment (PPE), including gloves and safety glasses, is essential. Good ventilation in the work area is also critical during application. Additionally, standard PU sealants can be vulnerable to UV degradation over time, which may cause chalking or discoloration unless they are painted or specifically formulated with UV inhibitors.

Safety First: Always review the product’s Safety Data Sheet (SDS) before use. This document outlines specific handling procedures and safety precautions to ensure a safe application.

Best Applications for PU Sealants

The superior strength and flexibility of polyurethane make it ideal for high-movement and structural applications. It excels in sealing expansion joints that experience constant stress. For example, PU sealants are used in bridge expansion joints, where they can reduce stress by over 35% and dramatically improve the joint’s service life. Other common uses include:

·Parking garage and pavement expansion joints

·Sidewalk and driveway control joints

·Industrial flooring

·Perimeter sealing for windows and doors in masonry

In these settings, polyurethane prevents water infiltration that leads to structural damage and corrosion.

Exploring Hybrid Polymer (MS Polymer) Sealants

Hybrid polymers represent a significant advancement in sealant technology. These materials, often called MS Polymers or Silyl-Terminated Polyethers (STPE), deliver a unique balance of performance features. They are engineered to overcome the limitations of traditional sealants.

The Best of Both Worlds

Hybrid sealants effectively combine the most desirable properties of polyurethane and silicone into a single product. This synergistic blend creates a versatile and durable solution for a wide range of sealing tasks.

·They offer the excellent durability and paintability of a polyurethane.

·They provide the superior weathering and UV resistance of a silicone.

This combination gives professionals a high-performance sealant that does not force them to choose between strength and weatherability.

Why Hybrids Excel

The exceptional performance of hybrid polymers comes from their unique chemistry. They are built on a silyl-modified polyether (SMP) backbone. This structure cures in the presence of moisture, forming strong and flexible siloxane bonds without releasing harmful byproducts. This process makes them a more environmentally friendly option.

Eco-Friendly Choice

Hybrid polymers are formulated without isocyanates and solvents. This results in very low Volatile Organic Compound (VOC) emissions, making them safer for installers and building occupants.

Their advanced formulation provides powerful adhesion to nearly any substrate, including damp surfaces. They remain permanently flexible, absorb vibrations, and resist shrinking or cracking over time.

Common Uses for Hybrid Polymers

The versatility of hybrid polymers makes them suitable for countless interior and exterior applications. They excel at creating durable, airtight seals that enhance energy efficiency and protect structures from the elements. Common uses include:

·Sealing around windows and doors

·Joints in siding and trim

·Roofing and gutter repairs

·Adhering panels and fixtures

Their ability to bond dissimilar materials makes them a go-to solution for modern construction projects.

Choosing the Right Waterproof Silicon Sealant Alternative

Selecting the correct sealant is crucial for a durable, long-lasting waterproof seal. The material you are working with dictates the best product for the job. A high-performance alternative to a standard Waterproof Silicon Sealant will provide superior adhesion, flexibility, and longevity when matched to the right surface.

For Concrete and Masonry

Polyurethane sealants are the top choice for concrete and masonry. These porous materials require a sealant that can create a tenacious bond deep within the surface. Polyurethane excels at this, providing exceptional adhesion and durability. It is ideal for high-movement expansion and control joints found in sidewalks, driveways, and foundations. These joints expand and contract with temperature changes, and polyurethane’s flexibility prevents the seal from cracking under stress.

For professional results, look for products that meet key industry standards. These specifications ensure the sealant has been tested for performance in demanding conditions.

·ASTM C920: Standard Specification for Elastomeric Joint Sealants

·ASTM C1193: Standard Guide for Use of Joint Sealants

·ASTM C1472: Standard Guide for Calculating Movement and Other Effects When Establishing Sealant Joint Width

Product Spotlight: For vertical cracks, a non-sag sealant like Sikaflex® + Concrete Fix is ideal because it will not drip or run. For horizontal surfaces like driveways, a self-leveling product like Loctite PL Self-Leveling Concrete Sealant or Sikaflex Self-Leveling Sealant fills cracks effortlessly and creates a smooth, level finish.

For Wood Siding and Trim

Wood is a natural material that moves, absorbs moisture, and requires painting for protection. For these reasons, a flexible, paintable sealant is a better choice than a typical Waterproof Silicon Sealant. Hybrid polymer sealants are an excellent option for wood siding and trim. They offer strong adhesion, remain permanently flexible to accommodate wood’s movement, and provide a perfectly paintable surface for a seamless finish.

The choice of sealant directly impacts the lifespan of exterior wood, which can last around 4 to 5 years if sealed correctly. The sealant creates a waterproof barrier against moisture, mold, and UV radiation.

| Sealant Type | UV Protection Level | Moisture/Mold Resistance | Best For Woods Like… |

|---|---|---|---|

| Oil-based (Solid/Opaque) | Highest | Excellent | Pine, Cedar, Oak, Ash |

| Water-based | Lower | Excellent | Alder, Birch, Maple |

| Clear | Lowest | Excellent | When natural look is desired |

Pro Tip: Maximize Trim Life

To ensure your exterior wood trim lasts as long as possible, follow these steps:1.Prime all six sides of the wood with an oil-based primer.

2.Install the trim and apply a high-quality hybrid or polyurethane sealant to the joints.

3.Apply a durable exterior paint as a topcoat. For added protection, a clear finish like Minwax Helmsman Spar Urethane can shield the wood from sun and water.

For Metal, Vinyl, and Window Perimeters

Sealing modern building materials like vinyl windows and coated metal roofing or siding presents a unique challenge. These non-porous, slick surfaces often feature special coatings like Kynar® that are designed to shed water and dirt. A standard sealant may struggle to achieve a lasting bond on these materials.

This is where hybrid polymer sealants demonstrate their advanced chemistry. They are specifically engineered for powerful adhesion to a wide range of difficult substrates, including plastics and coated metals. Their formulation ensures a durable, weatherproof seal that will not pull away or fail over time. This makes them a superior choice over a traditional Waterproof Silicon Sealant for these demanding applications.

Check the Spec Sheet: Always confirm sealant compatibility with coated materials. Products like Bostik Pro-MS 50 are engineered for Kynar®-coated metals, while Bostik DUO-SIL Ultra explicitly lists adhesion to both Kynar® and PVC substrates, making them ideal for vinyl window perimeters.

For Plastic and PVC Components

Plastics and PVC (polyvinyl chloride) are notoriously difficult surfaces for many sealants. Their smooth, non-porous nature can prevent a strong bond, leading to premature seal failure. While a standard Waterproof Silicon Sealant might seem like a quick fix, hybrid polymer sealants offer a more reliable and permanent solution. Their advanced chemical makeup is engineered to create a powerful, lasting bond with these slick materials.

Proper surface preparation is the key to success when sealing PVC trim boards and other plastic components. Following a precise process ensures the sealant adheres correctly and maintains its integrity.

PVC Priming Protocol

To achieve a professional-grade seal on vinyl or PVC, installers should follow these critical steps:1.Ensure the substrate is structurally sound, dry, and clean.

2.Remove all contaminants like dirt, oil, grease, old paint, or sealant residue.

3.Apply a specialized primer, such as Sika® Primer-173 or Sikaflex® Primer-449, to the vinyl surface.

4.Use a brush or clean cloth to apply a light, uniform coat of the primer at full strength.

5.Allow the primer to become tack-free before applying the sealant. The specific drying time is available on the primer’s Product Data Sheet.

6.Complete both the priming and sealing tasks on the same day for the best results.

For Interior Wet Areas like Kitchens and Baths

Interior wet areas demand sealants that do more than just block water. They must also resist mold, mildew, and, in kitchens, be safe for contact with food.

In commercial kitchens, food-safe sealants are not just a preference; they are a requirement. Agencies like the FDA regulate these products to ensure they are non-toxic and do not leach harmful chemicals into food. Food-grade silicone sealants, such as DAP’s COMMERCIAL KITCHEN 100% SILICONE, are certified to meet standards like NSF/ANSI Standard #51. This certification makes them safe for incidental food contact once cured and washed. These sealants create durable, waterproof seals around prep areas and appliances while resisting bacterial growth.

For bathrooms, the primary enemy is mold and mildew. Hybrid polymer sealants are an outstanding choice for sealing around showers, tubs, and sinks. Products like DAP AMP Kitchen & Bath Sealant are specifically designed for these high-moisture environments. This type of sealant is 100% waterproof, can be applied to damp surfaces, and dries in as little as 30 minutes. Its most important feature is a lifetime guarantee against mold and mildew growth, which keeps the seal looking clean for years. Other excellent options include siliconized acrylic-latex caulks like Hercules® Plumbers Caulk™, which offer a flexible, durable, and waterproof seal ideal for bathroom fixtures.

Other Specialized Sealant Options

Beyond polyurethane and hybrid polymers, several specialized sealants offer unique solutions for specific challenges. These products provide targeted performance where conventional options may fall short. Understanding their strengths helps professionals select the perfect material for any job.

Butyl Rubber Sealants

Butyl rubber sealants are non-curing, permanently tacky adhesives available in tape or caulk form. Their primary strength is creating an instant, watertight seal through adhesion. This makes them a popular choice for a wide variety of applications.

·Construction: Professionals use butyl tape for sealing roof joints, window flanges, and pipe penetrations.

·Automotive & Marine: It waterproofs car doors and headlights and seals deck joints on boats.

·Household: It is useful for emergency leak repairs and other DIY projects.

However, butyl rubber has limitations. It performs poorly in high temperatures above 100°C and can degrade when exposed to oils or strong solvents. Its extreme stickiness also makes removal difficult, often leaving behind a stubborn residue.

Pre-Compressed Foam Tapes

Pre-compressed foam tapes offer an innovative approach to sealing joints. These tapes consist of open-cell foam impregnated with an adhesive acrylic resin. They arrive on a roll in a compressed state. After application, the tape slowly expands to completely fill gaps, cracks, and uneven surfaces.

This stored energy creates continuous back-pressure against the substrates. The pressure, combined with the adhesive, forms a highly effective and durable seal. The tape maintains contact even as building materials expand and contract with temperature changes. It provides an excellent weather seal against wind-driven rain and is vapor permeable, allowing moisture to escape.

Advanced Acrylic Latex Caulks

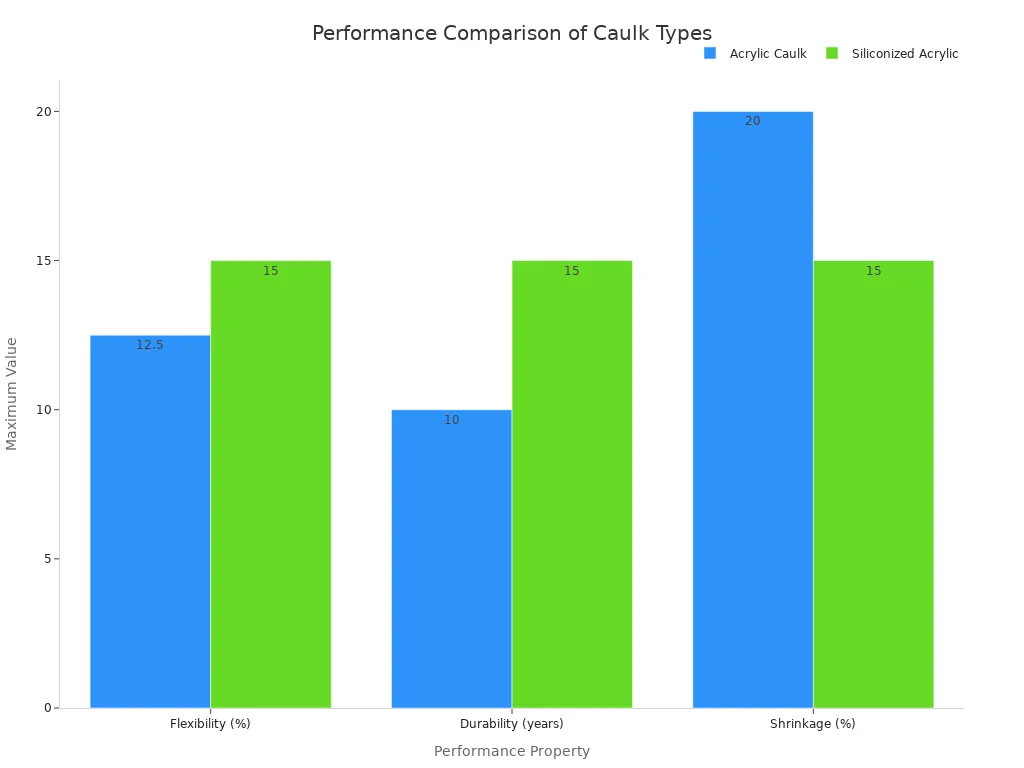

Advanced acrylic latex caulks, often called “siliconized” acrylics, offer a significant upgrade over standard acrylic products. The addition of silicone enhances performance while retaining the best features of acrylics, like easy water cleanup and excellent paintability.

The primary improvements are increased flexibility and better water resistance. While not fully waterproof like a pure silicone, a siliconized acrylic provides good protection for interior wet areas and sheltered exterior applications. It also shrinks less than standard acrylic caulk, reducing the chance of the seal pulling away from the joint over time.

Performance Boost

Compared to standard acrylics, siliconized versions offer:·Enhanced Flexibility: Movement capability increases from ±7.5% to ±12.5%.

·Improved Water Resistance: Better suited for areas with moisture exposure.

·Reduced Shrinkage: Less than 15% shrinkage for a more stable seal.

Application Tips for a Perfect Waterproof Seal

Applying a sealant correctly is just as important as choosing the right product. Proper technique ensures a durable, professional-looking waterproof seal that performs as expected. Following best practices for preparation, application, and curing makes all the difference.

Surface Preparation is Critical

A sealant’s bond is only as strong as the surface it adheres to. A clean, properly prepared substrate is essential for a long-lasting seal. Professionals follow a strict preparation protocol to guarantee powerful adhesion.

·First, they clean the surface thoroughly to remove all dirt, grease, oil, and other contaminants.

·Next, they inspect for and repair any damage like cracks or peeling paint.

·Finally, they apply a compatible primer if needed. Priming enhances the bond, especially on porous or challenging materials.

These steps ensure the surface has good wetting properties, allowing the sealant to spread and create a strong intermolecular bond.

Tooling for a Professional Finish

Tooling the sealant bead does more than create a clean look. It compacts the sealant into the joint, forcing out air pockets and ensuring full contact with the substrates. This process is critical for a watertight seal.

Pro Tip: Achieve a Flawless Finish

Professionals use a specific method for a perfect concave joint. They first insert a backer rod to control sealant depth. Then, they apply masking tape along the joint edges for clean lines. After applying a continuous bead of sealant, they use a tooling stick to press the sealant into a concave shape. Removing the tape immediately leaves a crisp, sharp edge.

Understanding Cure Times

Patience is a key part of the sealing process. Polyurethane and hybrid polymer sealants are moisture-curing, meaning they rely on atmospheric humidity to harden. Environmental conditions directly impact how long this takes. Higher temperatures and greater humidity will speed up the curing process. Conversely, cold temperatures and dry air can significantly slow it down. Always check the product’s technical data sheet for specific cure times and application temperature ranges to avoid premature failure.

Professionals find hybrid polymer sealants are the top alternative to a standard Waterproof Silicon Sealant for most general-purpose seals. They offer excellent paintability and durability. For heavy-duty, high-movement, or structural applications, polyurethane sealants remain the powerful choice. Selecting the right product ensures a successful, long-lasting result.

Final Check

Always read the manufacturer’s technical data sheet. This step confirms compatibility with specific materials and project requirements before starting work.

FAQ

Can I use polyurethane sealant in my bathroom?

Professionals typically recommend hybrid polymers for bathrooms. Polyurethane is very strong but can have a strong odor during its cure. Hybrid sealants offer excellent waterproofing and often include lifetime mold and mildew resistance, making them a superior choice for interior wet areas.

What is the main difference between hybrid and polyurethane sealants?

Polyurethane sealants provide the highest mechanical strength for structural jobs. Hybrid polymers offer the best all-around performance. They combine good strength with excellent UV resistance and paintability, making them more versatile for general-purpose sealing projects.

How do I remove old polyurethane or hybrid sealant?

Removal requires a two-step process. First, professionals cut and scrape away the bulk of the old sealant with a utility knife or specialized tool. Then, they use a chemical solvent designed for sealants to soften and remove any remaining residue.

Safety Note: Always work in a well-ventilated area and wear appropriate safety gear, including gloves and eye protection, when using chemical solvents.

Are hybrid polymers safe for indoor air quality?

Yes, hybrid polymers are an excellent choice for indoor use. They are formulated without isocyanates and have very low Volatile Organic Compound (VOC) emissions. This makes them a safer option for installers and building occupants, contributing to better indoor air quality.

Post time: Oct-31-2025