You want quick dry sealant to work well. First, make sure surfaces are clean and dry. Sealant does not stick if there is dust, oil, or water. Most sealant problems happen because of this. Junbond Marine Sealant helps make sealing easier.

·If you rush, you may make mistakes

·If surfaces are dirty, sealant will not stick

·Work fast but be careful to get a good finish.

Prep for Quick Dry Sealant

Surface Cleaning

You want your sealant to last, so start with proper surface preparation. Clean, dry, and oil-free surfaces help the sealant stick and cure well. If you skip this step, you risk poor adhesion and a weak seal.

·Remove dirt, dust, and grease using a cleaner like isopropyl alcohol or mineral spirits.

·Wipe the area and let it dry completely.

·For wood, grab an electronic moisture meter. Keep moisture below 15% for best adhesion. High moisture can cause wood to swell and break the sealant bond.

Tip: Junbond recommends checking moisture content before applying sealant to timber decking. This simple step helps you avoid problems later.

Removing Old Sealant

Old sealant can block new adhesion. Use a sharp utility knife or scraper to cut away old material. Mechanical removal works well for most jobs.

·Keep your blades sharp for safety and efficiency.

·If you find stubborn spots, try a chemical remover, but test it first to make sure it won’t damage the surface.

After you remove the old sealant, clean up any loose bits. Vacuum or brush away dust and debris. This step is key for strong adhesion.

Protecting Edges

Neat edges make your sealant job look professional. Painter’s tape helps you get clean lines and protects surfaces next to the joint.

·Press the tape down firmly so it sticks well.

·Remove the tape right after you finish smoothing the sealant bead. Waiting too long can peel paint or mess up the finish.

Note: Good surface preparation helps the tape stick and keeps your sealant edges sharp. Junbond Marine Sealant works best when you follow these steps.

Following these steps gives you a strong bond and a smooth finish. You set yourself up for success with Junbond and get the best adhesion possible.

Choose and Apply Silicone Sealant

Select the Right Sealant

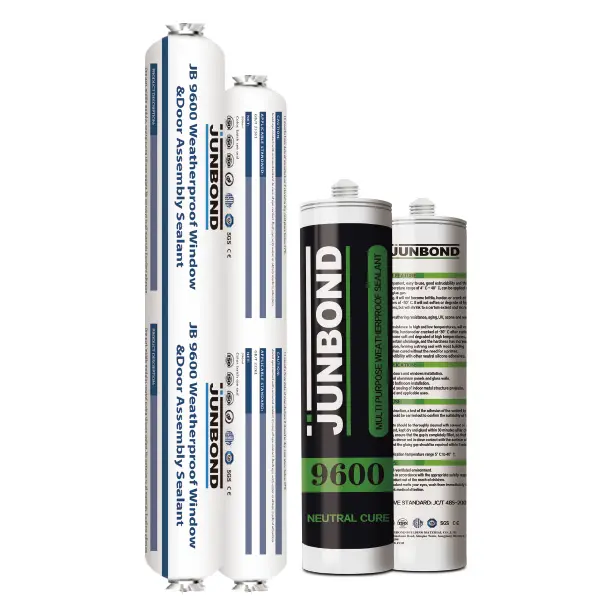

You want a sealant that stands up to tough jobs. Junbond Marine Sealant is a smart choice for marine and demanding applications. It works well on boats, yachts, and even timber decking. You get strong adhesion, flexibility, and a finish that lasts. This sealant resists UV rays, water, and harsh weather. It also handles both seawater and fresh water, so you do not have to worry about the elements.

Here is a quick look at what makes Junbond Marine Sealant a top pick:

| Feature | Description |

|---|---|

| One-component | Easy to use, no mixing needed |

| Non-corrosive | Safe for many materials |

| Sandable | Smooth finish after curing |

| Semi-self leveling | Less effort for a neat look |

| UV and weather resistant | Stays strong in sun and storms |

| Resistant to seawater and fresh water | Great for marine conditions |

When you choose the right sealant, you set yourself up for success. You get both speed and quality in your project.

Gather Tools

Before you start, gather all the tools you need for sealant application. Having the right tools makes the job easier and helps you apply silicone sealant with confidence.

| Tool Type | Function |

|---|---|

| Caulking gun | Dispenses the sealant smoothly and evenly |

| Silicone Sealant Tool Kit | Helps you apply and finish edges for a clean look |

| Gloves | Keeps your hands clean and safe |

| Smoothing tool | Shapes the bead for a professional finish |

| Cleaning supplies | Removes spills and keeps the area tidy |

| Precision toolset | Reduces mistakes and helps with tricky spots |

You want to keep everything within reach. This way, you can quickly apply silicone sealant and keep your work moving.

Quickly Apply Silicone Sealant

Now you are ready to apply silicone sealant. Start by checking the temperature and humidity. The best range is 50°F to 90°F (10°C to 32°C). Good airflow helps the sealant dry and keeps fumes away. Avoid direct sunlight, which can cause uneven drying.

Cut the tip of the caulk tube at a 45-degree angle. This shape helps you push the sealant into the joint. Hold the caulking gun at a 45-degree angle to the surface. Use steady pressure on the trigger. Start with light pressure and add more if you need a bigger bead. Move the gun slowly and keep the bead even.

·Cut the tube tip at a 45-degree angle for smooth application.

·Hold the gun at a 45-degree angle to the joint.

·Keep steady pressure for a uniform bead.

·Work in small sections. Try to finish each section within 5-10 minutes for best results.

You want to apply silicone sealant in one smooth motion. This helps you get both speed and quality in your sealant application.

Smoothing and Finishing

After you apply silicone sealant, smooth the bead right away. Use a sealant finishing tool or a damp finger dipped in soapy water. This step gives you a neat, professional look and helps the sealant bond well.

·Place painter’s tape above and below the joint for crisp lines.

·Smooth the bead with steady, gentle pressure.

·Remove the tape right after smoothing for sharp edges.

If you see extra sealant, clean it up before it dries. For stubborn spots, warm the area with a hairdryer, then gently scrape with a plastic tool. Wipe away any residue with a cloth and soapy water.

You want your sealant application to look clean and last a long time. Careful smoothing and quick cleanup make all the difference when you apply silicone sealant.

Post-Application Care

Inspection and Touch-Ups

You want your sealant job to last, so take a close look after you finish. Check for gaps, bubbles, or cracks. These problems can show up if you test the area too soon or if the weather is cold or humid. Sunlight can also cause the outside to dry faster than the inside. Use a flashlight or a simple inspection tool to spot any flaws. If you see a bubble, cut it gently with a sharp blade and smooth the area. For cracks, clean the spot and add a bit more sealant. If you notice peeling, remove the loose part and reapply after cleaning.

Tip: Wait for the full curing time before doing any water or pressure tests. Rushing can damage your work.

Here’s a quick look at helpful inspection tools:

| Tool Type | Purpose |

|---|---|

| Bead Inspection | Checks width and consistency of the sealant |

| 3D Sensor System | Finds gaps and checks seam quality |

Cleanup Tips

You want to keep your tools in good shape and protect the environment. Wipe off extra sealant from tools before it dries. Use a cloth and a little soapy water for fresh spills. For stubborn spots, try a plastic scraper. Always read the label for proper disposal instructions. Use up leftover sealant or give it away if you can. For water-based cleaners, you can usually pour them down the drain. Throw solid waste in the trash, but check with your local waste facility for anything hazardous.

Junbond recommends letting the sealant cure fully. Curing time depends on temperature, humidity, and how thick you applied it. Follow these steps, and you’ll get a strong, lasting seal every time.

You want the best results with quick dry sealant. Follow these steps for a strong, clean finish:

1.Prep the area and use painter’s tape.

2.Apply quick dry sealant smoothly.

3.Smooth the bead and remove tape fast.

4.Let the sealant cure.

Avoid applying quick dry sealant to wet surfaces or skipping cleaning. Junbond helps you get a professional look every time.

FAQ

How long does Junbond Marine Sealant take to cure?

You can expect Junbond Marine Sealant to cure in 24 to 48 hours. Temperature and humidity may affect the drying time.

Can I paint over Junbond Marine Sealant?

No, you should not paint over Junbond Marine Sealant. The sealant is designed to stay flexible and exposed for best performance.

What should I do if I make a mistake during application?

Tip: Wipe away fresh sealant with a damp cloth right away. If it dries, gently scrape it off and reapply for a clean finish.

Post time: Dec-03-2025