A high-quality Fireproof Sealant is absolutely worth the investment for ensuring code-compliant fireblocking and providing tested peace of mind.

The value of DAP’s product, however, depends entirely on its specific use. Several key factors determine its ultimate worth:

·Local building code requirements

·The type of penetration being sealed

·Its performance against non-fire-rated alternatives

What Am I Paying For? The Science Behind Fire Stop Sealant

The higher price of a fire-rated sealant reflects its specialized chemical engineering. Unlike standard caulks designed for simple gap-filling, this product performs a critical safety function during a fire. Understanding its unique properties clarifies the investment.

The Intumescent Difference: How It Works

The key technology behind this sealant is its intumescent property. At its core, the sealant is an acrylic polymer, a type of acrylic latex material that applies smoothly like a high-quality caulk. However, its formulation contains special additives that remain dormant under normal conditions.

When exposed to intense heat, a dramatic transformation occurs.

1.Activation: The chemical reaction begins at temperatures around 200-250°C (392-482°F).

2.Expansion: The sealant rapidly swells, expanding to many times its original volume.

3.Charring: It forms a hard, dense char that acts as an insulating barrier.

This char effectively blocks the passage of flames, toxic smoke, and superheated gases through gaps, containing the fire to its point of origin and protecting escape routes.

Standard Caulk vs. Fire Stop: A Performance Mismatch

Using a standard acrylic latex caulk in an application requiring a fire stop is a critical mistake. The two products are engineered for completely different outcomes. Standard caulks are typically organic materials designed for flexibility and weather resistance. A fireproof sealant prioritizes heat resistance and compartmentation.

Note: A standard caulk will melt, burn, and shrink away from heat, creating a pathway for fire and smoke to spread rapidly. It offers no meaningful resistance in a fire scenario.

Furthermore, firestop products are evaluated differently. They are tested as a component within a complete firestop system—the wall or floor assembly, the penetrating item (like a pipe or cable), and the sealant itself. This entire system earns a fire rating (e.g., 1 to 4 hours). A standard caulk undergoes no such system testing and carries no fire rating, making it unsuitable and non-compliant for these critical life-safety applications.

Understanding This Fireproof Sealant: Key Product Specs

Beyond its fire-stopping science, a product’s practical specifications determine its usability on a job site. This Fireproof Sealant combines high-performance safety features with user-friendly application characteristics. A professional must understand these specs to achieve a compliant and durable seal.

Cure Time and Application Realities

As a water-based acrylic latex sealant, its curing process depends heavily on environmental conditions. The product applies smoothly and cleans up easily with water before it cures. However, applicators must account for the surrounding atmosphere to ensure a proper set.

Curing and full adhesion time will vary depending on temperature and humidity. Low temperatures or high humidity will extend the time required for the sealant to become tack-free and fully cure.

Planning an application during moderate weather conditions ensures the most predictable and efficient curing cycle.

Adhesion, Durability, and Approved Materials

This sealant provides an excellent, durable bond to a wide array of common construction materials. Its formulation ensures it adheres strongly, creating a long-lasting barrier. The product is approved for use on many substrates, including:

·Wood (painted & unpainted)

·Drywall and Plaster

·Most metals, including copper and aluminum

·Most plastics and vinyl

·Concrete and natural stone like granite

·Glass and ceramic

This versatility makes it a reliable choice for sealing penetrations through various assemblies. Its durability is not just a claim; it is verified through rigorous third-party testing. Firestop systems are evaluated under standards like ASTM E814 and UL 1479. These tests assess a system’s ability to block flames and heat. They also measure air leakage (L Rating) and water resistance (W Rating), proving the sealant’s integrity against multiple elements, not just fire.

Where Is It Worth the Investment? Critical Applications

The decision to use this premium sealant hinges on a single question: does the application require a fire-rated assembly? The product’s value is directly tied to its role in life-safety systems. Understanding where it is essential versus where it is unnecessary is key to a smart investment.

High-Value Use: Sealing Service Penetrations

The primary and most critical use for this sealant is for fireblocking around service penetrations in fire-rated walls and floors. Building codes mandate the protection of these openings. A hole cut for a pipe or wire effectively voids a wall’s fire rating until it is properly sealed with a tested firestop system. This sealant restores the integrity of the assembly.

Building codes like the International Building Code (IBC) and NFPA Life Safety Code are very clear on this. They require firestop systems for penetrations to contain fire and smoke to their area of origin. Common examples requiring a proper seal include:

·Pipes, conduits, and ducts passing through walls or floors.

·Protective sleeves for cable bundles.

·Membrane penetrations, such as electrical outlet boxes and utility panels set into a wall.

Different penetrations have specific requirements. For instance, pipes passing through a two-hour rated wall often must run through a larger metal sleeve. An applicator then fills the gap between the pipe and the sleeve with an intumescent sealant. Similarly, electrical wire bundles and nonmetallic boxes must be sealed according to their UL-listed system to prevent fire from passing through the wall cavity.

Professional Tip: Membrane penetrations, like electrical boxes, are a frequent point of failure in inspections. Protecting the back of these boxes with listed materials like putty pads, in conjunction with sealing the surrounding gap, is essential for compliance in rated walls.

Using a high-performance Fireproof Sealant in these situations is not just a good idea—it is a legal and ethical obligation. It ensures the building meets code, passes inspection, and most importantly, provides critical protection for occupants in the event of a fire.

Low-Value Use: General Drafts and Gaps

Conversely, using this specialized product for general-purpose sealing is not a worthwhile investment. Applications where a fire rating is not required do not benefit from the sealant’s advanced intumescent chemistry. These are situations where a standard caulk is the correct and more economical choice.

Consider these common low-value scenarios:

·Sealing gaps around window and door frames in non-rated walls.

·Filling cracks in drywall or plaster for cosmetic repairs.

·Closing small gaps along baseboards to stop drafts.

·General sealing in kitchens and bathrooms for sanitary purposes.

In these cases, the primary goal is to block air, moisture, or insects, or simply to achieve a clean aesthetic finish. A standard acrylic or silicone caulk is designed for these tasks, offering excellent flexibility and adhesion at a fraction of the cost.

The rule is simple: if the wall or floor assembly is not fire-rated, the gap does not require a fire-rated sealant.

Investing in a premium Fireproof Sealant for these jobs provides no additional safety benefit and is an unnecessary expense. The money is better spent on a product specifically formulated for flexibility, paintability, or mildew resistance, depending on the specific need.

Is the Application Effort Worth It?

A product’s performance depends heavily on correct application. This fireproof sealant is designed for professional results, but the effort an applicator puts into the details directly impacts its effectiveness and compliance. The process is straightforward, yet precision is non-negotiable.

Tooling, Smoothing, and Water Cleanup

Applying this sealant feels familiar to anyone experienced with high-quality acrylic caulks. It dispenses smoothly from the tube and adheres well to approved surfaces. The key to a clean, professional finish lies in working efficiently within the product’s specified time frame.

Working Window: An applicator has a tooling time of 10-20 minutes before the sealant begins to skin over. This window is crucial for smoothing the bead and ensuring full contact with the substrate.

Once the bead is applied, it can be tooled with a wetted finger or a specialized tool to create a neat, uniform seal. A significant advantage of its water-based formula is the simple cleanup process. Before it cures, excess sealant and tools can be cleaned easily with just soap and water, saving time and eliminating the need for harsh solvents on the job site.

The Importance of Correct Application Depth

Correct application depth is not a matter of preference; it is a critical life-safety requirement. The sealant’s ability to stop fire is directly tied to applying the right amount of material. A bead that is too thin will fail under heat, rendering the firestop system useless.

Applicators must follow specific guidelines based on the joint or penetration being sealed.

·For joints expecting movement, the sealant depth should be a minimum of 1/8 inch and a maximum of 1/2 inch.

·The joint’s width-to-sealant-depth ratio should be at least 2:1 to accommodate movement without compromising the seal.

Industry guidelines for tested firestop systems mandate a minimum application depth, often around 25 mm (approximately 1 inch) for certain penetrations. If the applied sealant is thinner than this specified requirement, there is no assurance of fire protection. This failure to meet the minimum depth means the seal does not carry the intended fire rating and will not pass a building inspection. The effort to apply the correct depth is absolutely worth it, as it is the only way to guarantee compliance and safety.

Cost vs. Consequence: The Financial Breakdown

When evaluating any building material, the financial analysis extends beyond the sticker price. For a life-safety product like fireproof sealant, the choice between a premium option and a cheaper alternative involves weighing a small upfront saving against potentially catastrophic long-term consequences. A professional considers not just the cost of the tube, but the cost of failure.

Price Per Tube vs. Cheaper Alternatives

On the surface, the price difference between a specialized fireproof sealant and a standard caulk is significant. A contractor looking at a project budget will immediately notice the disparity. For example, a 10.1 fl oz tube of DAP Fire Stop Fire-Rated Silicone Sealant costs approximately $15.50 when purchased in bulk. This price reflects its advanced intumescent chemistry and the extensive testing required to certify it for life-safety applications.

In contrast, a standard all-purpose caulk is far more economical. A product like DAP ALEX Painter’s Acrylic Latex Caulk, designed for general sealing and cosmetic finishing, has a much lower price point. The cost varies with volume, but the savings are clear.

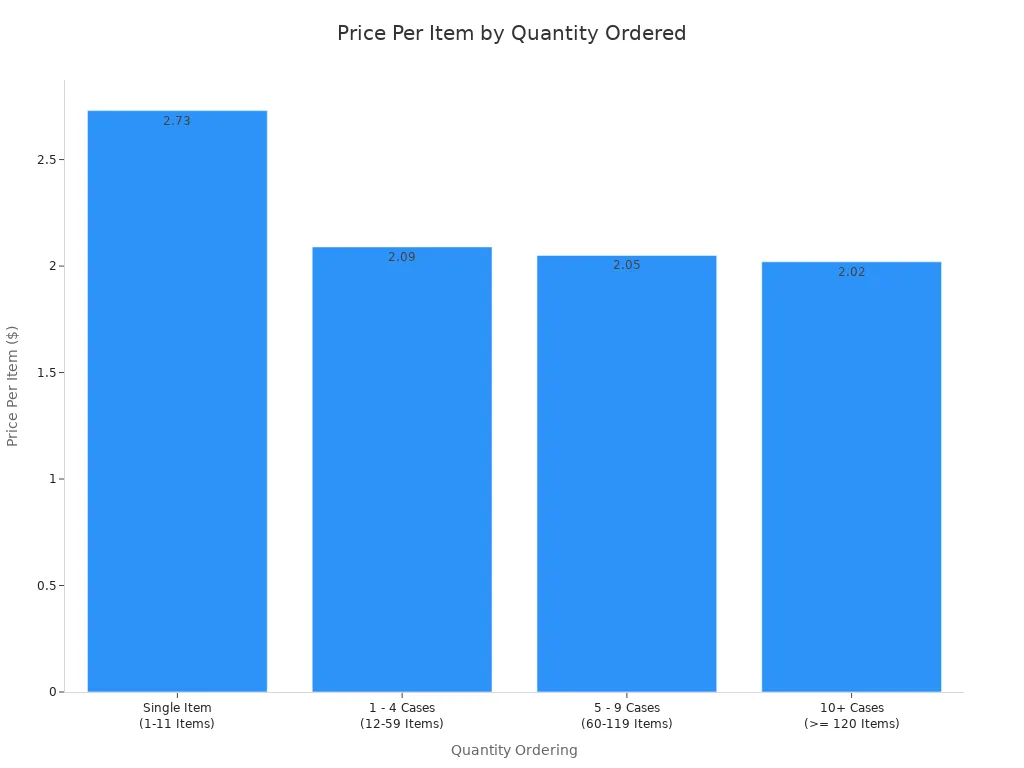

| Item Size | Quantity Ordering | Price Per Item |

|---|---|---|

| 10.1 fl oz. cartridge | Single Item (1-11 Items) | $2.73 |

| 10.1 fl oz. cartridge | 1 – 4 Cases (12-59 Items) | $2.09 |

| 10.1 fl oz. cartridge | 5 – 9 Cases (60-119 Items) | $2.05 |

| 10.1 fl oz. cartridge | 10+ Cases (>= 120 Items) | $2.02 |

The standard caulk is an excellent product for its intended purpose. It meets ASTM C834 standards for durability and is designed for paintability and easy water cleanup. However, it lacks the critical fire-resistant properties of a firestop sealant. The price difference is not arbitrary; it represents two entirely different technologies for two entirely different jobs. Choosing the cheaper option for a fire-rated penetration is a fundamental mismatch of product to application.

The Hidden Cost of Non-Compliance and Failed Inspections

The true financial risk emerges when an installer uses a non-rated product in a required firestop application. The initial savings of a few dollars per tube quickly evaporate when faced with the hidden costs of non-compliance.

The most immediate consequence is a failed building inspection. When an inspector identifies improper firestopping, work must stop. This triggers a cascade of expensive problems:

- Rework Labor: The contractor must pay workers to scrape out the incorrect caulk.

- Material Waste: The incorrectly used caulk is a sunk cost.

- Repurchase: The contractor must then buy the correct fireproof sealant anyway.

- Project Delays: The time lost waiting for rework can lead to penalties and disrupt other trades on the job site.

Beyond the job site, non-compliance creates significant long-term financial liabilities. Insurance companies assess risk meticulously. Buildings with inadequate or non-compliant fire protection systems are considered high-risk properties. This can lead to substantially increased insurance premiums. Most commercial and residential insurance policies mandate adherence to local fire safety codes. Failure to comply can not only drive up costs but, in some cases, may lead an insurer to decline coverage for the property altogether.

The ultimate cost is liability. In the event of a fire, improper firestopping can become the focus of intense legal scrutiny.

While proving liability can be complex, legal proceedings involving firestop companies, such as the federal case COVACHUELA v. JERSEY FIRESTOP LLC, show that these issues do end up in court. Other appellate court cases demonstrate the critical role of expert testimony in determining whether a failed firestop contributed to damages. For a contractor, the cost of defending against a lawsuit—regardless of the outcome—can be financially devastating. The small amount saved by using a cheaper caulk is insignificant compared to the potential for project delays, higher insurance costs, and catastrophic legal liability.

A high-quality Fireproof Sealant is an essential investment for safety and code compliance. Its value is highest when sealing critical openings mandated by building codes, including:

1.Through Penetrations in walls or floors.

2.Membrane Penetrations like electrical boxes.

3.Joints between fire-rated assemblies.

For general draft-stopping or cosmetic gaps in non-rated walls, a standard caulk is the correct, economical choice. Professionals should purchase this product for life-safety applications and skip it for general-purpose sealing.

FAQ

Can I use this sealant for my kitchen or bathroom?

This sealant is not ideal for general kitchen or bathroom use. A standard sanitary caulk offers better mildew resistance and flexibility for those applications. Use fireproof sealant only where a fire-rated assembly is required by code.

How long does it take for the sealant to become fireproof?

The sealant provides its fire-stopping properties once it is fully cured. Cure time varies based on temperature, humidity, and application depth. An applicator must allow the sealant to cure completely to ensure it performs as tested in a fire.

What happens if I apply a thinner layer than required?

Applying a layer thinner than the specified depth voids the fire rating. The seal will not provide the tested level of protection and will fail a building inspection. Correct depth is a non-negotiable requirement for life safety.

Important: Always consult the UL system sheet for the specific penetration. It dictates the required sealant depth and annular space for a compliant firestop.

Is this sealant waterproof?

Yes, this sealant is tested for water resistance. Products with a “W Rating” have passed tests confirming they maintain their seal even after exposure to water. This ensures durability in environments where moisture may be present, protecting the integrity of the firestop system.

Post time: Nov-12-2025